First of all you need to get some raw materials to use and most are available from the local model shop or eBay. There are firms that supply floatmaking materials but you need to buy massive quantities.

12mm balsa dowel for the float body.

Some hollow plastic tube either colored or clear, I use 2mm thick.

Fiberglass float stems, I am using 1mm in the photos. You can also use wire or carbon depending on your preference.

A pot of yacht varnish.

A pot of acrylic model paint if you wish to make the float body a certain colour.

Some fire orange model paint and a matt white for painting the tip.

Some cellulose sanding sealer.

a selection of sand paper in 60, 120, and 240 grades.

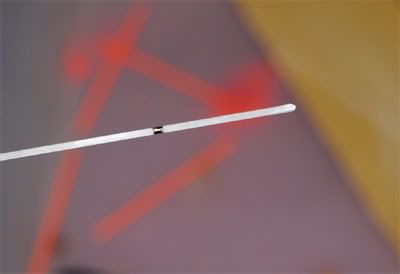

First of all you cut a piece of the fiberglass float stem to the required length. It doesn't matter if it is too long as you can always trim it up. You need to make a mark on it about 2cm down so you know how much of the stem is glued into the tip.

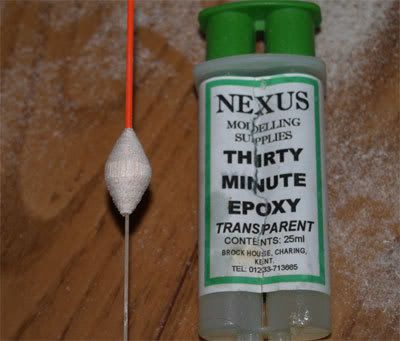

Then you need to cut a length of the hollow plastic float tip material about 5-6cm is about right but again you can trim it up when the float is finished. This is glued in place with an epoxy resin glue like Araldite

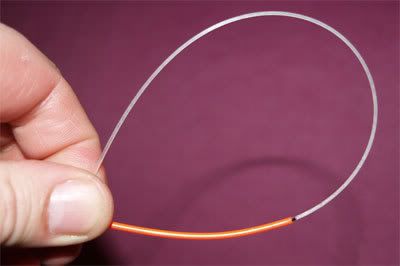

This give the float immence strength as you can see in the photo below making it unbrakeable in normal use.

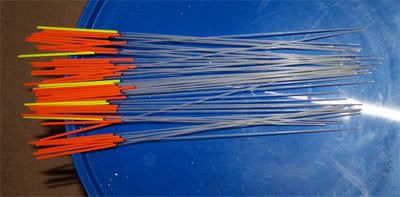

Here is a batch ready to go.

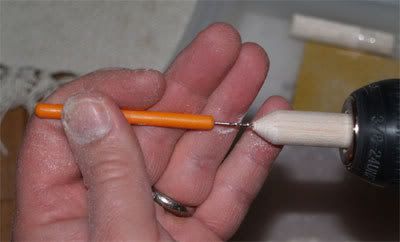

Next you need to cut a length of 12mm balsa dowel about 12cm long and fix it in the drill ready to shape the body. This is done by spinning up the balsa and using the 60 grade sandpaper.

Leave a bit flat on the end and don't sand it to a point so you can then drill a small hole down the middle. I use a small Drennan boilie drill.

You can now use the 60 grade sandpaper to shape the rest of the float body.

Once you have the rough shape of the float body cut it off using a small hacksaw.

This can now be glued on the float stem with epoxy resin glue. It will end up looking like this.

You can now fix the float back in the drill and fine tune the shape of the float body, smoothing it off with the fine sandpaper.

With a bit of luck it should end up looking like this! Ready for painting.

I will now give the float body 2 coats of sanding sealer (sand lightly after the first coat), 1 coat of colour if wanted, then it is finished off with 2 coats of varnish.

When dry you can now trim up the tip and stem to the reqired length. The tip can also be painted if needed. You should end up with something looking like this ready for the eyes to be glued in place again using epoxy resin glue.

(Photos Taken By Deborah Gilbert)

hello do you have any idea what kind of plastic i can use to make float?

ReplyDeleteSimply wish to say your article is as astonishing. The clarity in your post is simply great, and I could assume you are an expert on this subject. Same as your blog i found another one Sohman Epoxy .Actually I was looking for the same information on internet for

ReplyDeleteEpoxy solvent and came across your blog. I am impressed by the information that you have on this blog. Thanks a million and please keep up the gratifying work.